About Product

Indus trade links is the dealer for Gates make hydraulic hose and their assemblies in Kerala since 1996. These hoses are DNV certified and meet SAE, DIN and EN agency specifications. Over the years, Gates has enhanced its reputation by catering the highest quality products and services. The same dedication to quality continues today with the Gates Quality commitment. The meaning of quality in Gates is to meet or exceed customer expectation/satisfaction with world standard products and service experiences that are exceeding the competition parameters. The quality practices of Gates ensure that each “Made in India” product meets the industry’s highest standards and qualifies as Gates global hydraulic and industrial products for fluid conveyance. Gates has a substantial presence in the OE market which they have acquired through their quality products and superior technical know-how. The list of OE clients include JCB, Caterpillar, Atlas Copco, Hyundai, Sany, L&T, Mahindra, Midco etc.

There are 3 categories of hydraulic hose in Gates which covers a comprehensive range of hydraulic applications; low pressure, medium pressure and extremely high pressure range. There is also an additional range called megasys in Gates which is used in applications where a constant pressure is maintained throughout. Rock breaker application is a challenging portfolio where Gates R15 and the newly launched MXG hoses have proved the supremacy in the performance.

Constant Pressure

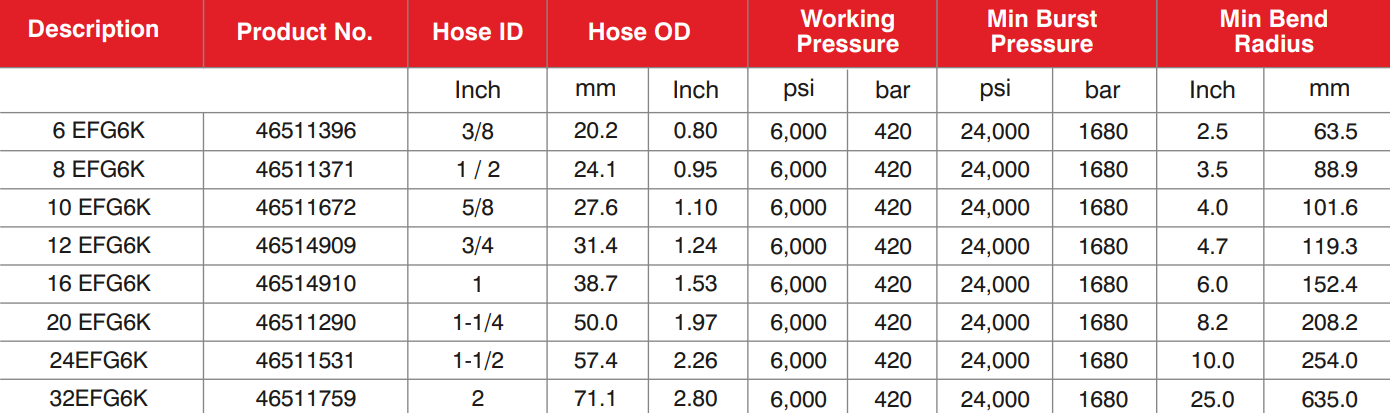

EFG6K Megasys Spiral Wire Hose-SAE 100R15

Meets Flame Resistance Acceptance Designation "MSHA 2G"

*Also available in Megatuff covers

Recommended for: Extremely high pressure, high-impulse action such as hydrostatic transmissions, EFG6K is designed to meet all requirements of SAE 100R15 specifications and performance requirements of EN 856 4SP (-6, -8, -10 and -12) and EN 856 4SH (-12, -16 and -20) and ISO 3862 Tyre R15 (-6, -8, -10, -12, -16, -24) Compatible with biodegradable hydraulic based fluids like polyolester, polyglycol and vegetable oil as well as standard petroleum based fluids. Superior impulse performance: tested to 1,000,000 impulse cycles

-40°C to +121°C

Construction:Tube : Black, oil resistant synthetic rubber [Nitrile-Type C].

Reinforcement: Four altemating layers of spiraled, high tensile steel wire.

cover :Black, oil resistant, synthetic rubber [Neoprene - Type A].

Reinforcement : Four (Six for-20, -24, -32) alternating layers of spiraled, high tensile steel wire.

Coupling: GS (Thru-6 to-20) & GSM (Thru-24 &-32)

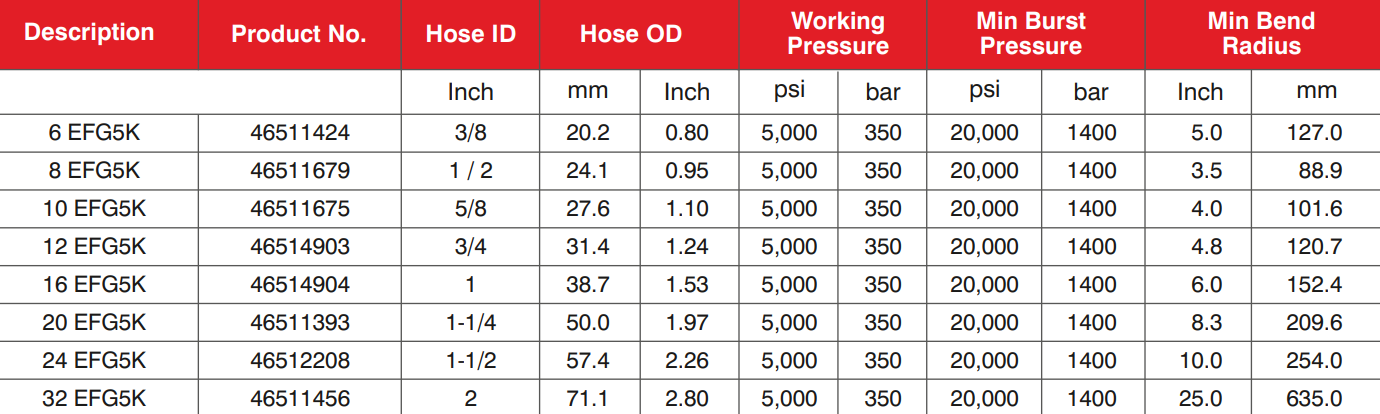

EFG5K Megasys Spiral Wire Hose-SAE 100R13

Meets Flame Resistance Acceptance Designation "MSHA 2G"

*Also available in Megatuff® covers

Recommended for: Extremely high hydraulic applications EFG5K is designed to meet all requirements of SAE 100R13 specifications and performance requirements of EN 856 4SH (-24 and -32) and EN 856 R13 and ISO 3862 Type R13 (-12, -16, -20, -24, -32). Compatible with biodegradable hydraulic based fluids like polyolester, polyglycol and vegetable oil as well as standard petroleum based fluids. Superior impulse performance: tested to 1,000,000 impulse cycles

-40°C to +121°C

Construction:Tube :Black, oil resistant synthetic rubber [Nitrile-Type C].

cover :Black, oil resistant, synthetic rubber [Neoprene - Type A]. Dual red strip layline

Reinforcement : Four (Six for-20) alternating layers of spiraled, high tensile steel wire.

Coupling: GS (Thru-6 to -20) & GSM (Thru-24 &-32)

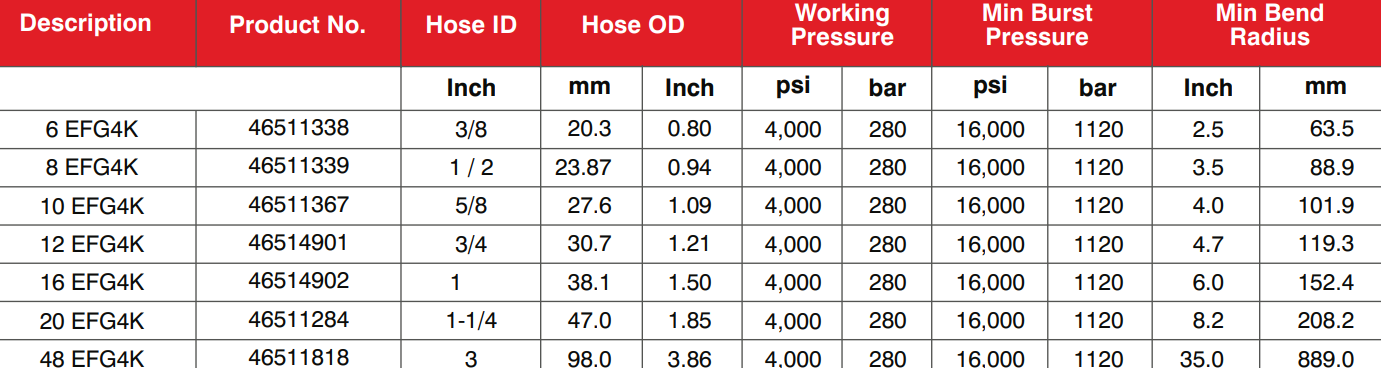

EFG4K Megasys Spiral Wire Hose-SAE 100R12

Meets Flame Resistance Acceptance Designation "MSHA 2G"

*Also available in Megatuff® covers

Recommended for: Extremely high pressure high-impulse applications. Exceeds all performance requirements of ISO 18752 Grade D, ISO 3862 type R12, SAE 100R12 and EN856R12. Compatible with biodegradable hydraulic fluids like polyolester, polyglycol and vegetable oil as well as standard petroleum based fluids, Superior impulse performance: tested to 1,000,000 impulse cycles.

-40°C to +121°C

Construction:Tube :Black, oil resistant synthetic rubber [Nitrile-Type C].

cover :Black, oil resistant, synthetic rubber [Neoprene - Type A]. Blue strip with white print layline

Reinforcement : Four alternating layers of spiraled, high tensile steel wire.

Coupling: GS

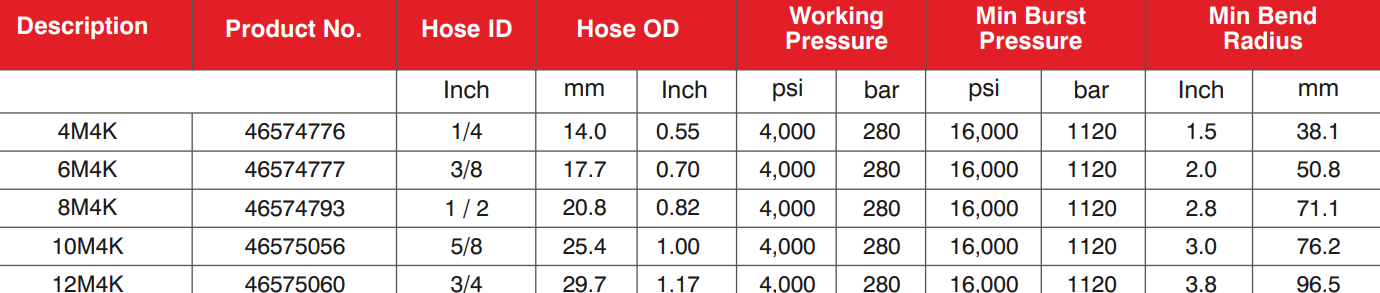

Megasys Wire Braid Hose-M4K

Exceeds SAE 100R19, ISO 11237 R19 and ISO18752 Grade B

R19 Flame resistant MSHA-2G

Recommended for: M4K is designed to meet all requirement of SAE 100R1 (-4) andSAE100R2 (-6, -8, 10) and SAE 100R12 (-12).Compatible with biodegradable hydraulic based fluids. Superior impulse performance: tested to 6,00,000 impulse cycles

-40°C to +100°C

Construction:Tube :Black, oil resistant, synthetic rubber (Nitrile - Type C).

cover :Black, synthetic rubber (Modified Nitrile - Type C2), resists abrasion, oil, weather, ozone

Reinforcement : Two braids of high tensile steel wire.

Coupling: G (MegaCrimp®)

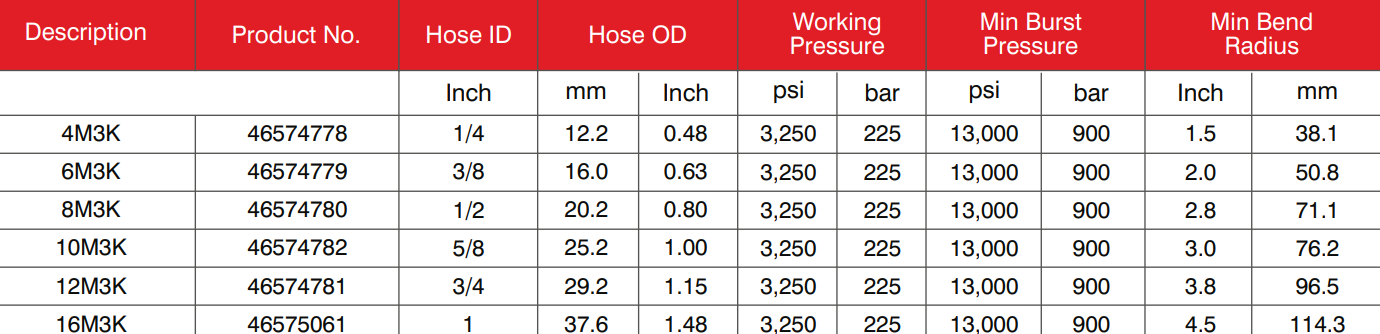

Megasys Wire Braid Hose-M3K

Meets Flame Resistance Acceptance Designation "MSHA 2G", and ISO11237 R17

Recommended for: High-pressure hydraulic oil lines. Exceeds ISO 18752 Grade B, SAE 100R17 and ISO11237 R17working pressure, minimum bend radius requirements and performance requirements of EN 857 1SC. M3K hose has smaller exterior dimensions and significantly tighter bend radius than other SAE 100R1 and 100R2 hose.

-40°C to +100°C

Construction:Tube :Black, oil resistant, synthetic rubber (Nitrile).

cover :Black, oil, abrasion and weather & ozone resistant, synthetic rubber (Modified Nitrile Type C2)

Reinforcement : Braided, high-tensile steel wire; -4, -6, -8 have one braid, -10, -12, -16 have two braids.

Coupling:G (MegaCrimp®)

Extremely High Pressure

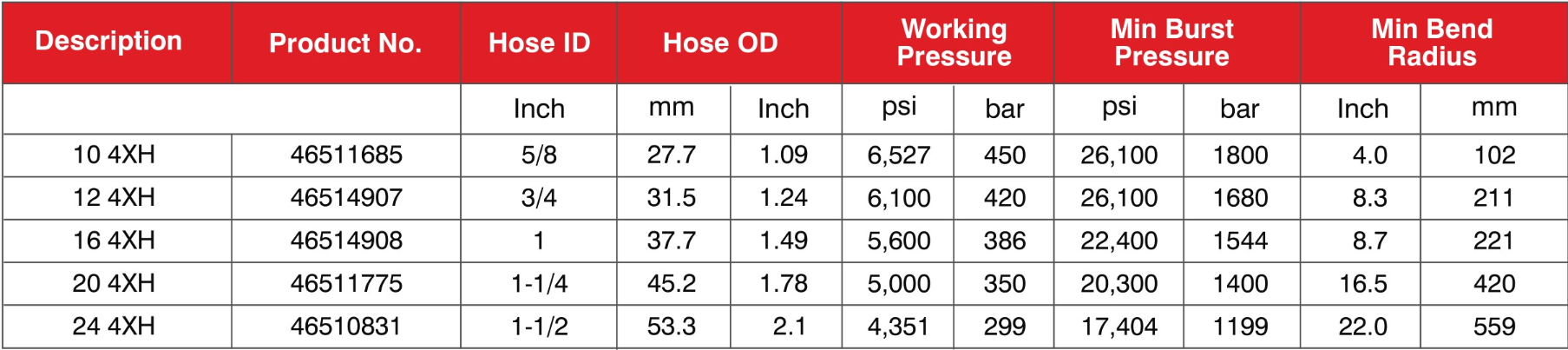

4XH Spiral Wire Hose-EN856 4SH ISO 3862

Meets Flame Resistance Acceptance Designation "MSHA IC-4/17"

Recommended for: Extremely high hydraulic applications. Most flexible EN 856 4SH Hose in industry Compatible with biodegradable hydraulic fluids like synthetic ester, polyglycol and vegetable oil as well as standard petroleum based fluids, superior impulse performance: tested to 1,000,000 impulse cycles

-40ºC to +100ºC

Construction:Tube : Black, ol resistant synthetic rubber (Nitrile-Type C). Reinforcement: Four altemating layers of spiraled, high tensile steel wire.

cover :Black, oil resistant, synthetic rubber [Neoprene - Type A].

Reinforcement : Four (Six for – 20) alternating layers of spiraled, high tensile steel.

Special Features:

Designed for maximum flow rates.

Minimal Kinking or Collapsing during use and handling.

Cover Designed for superior abrasion resistance.

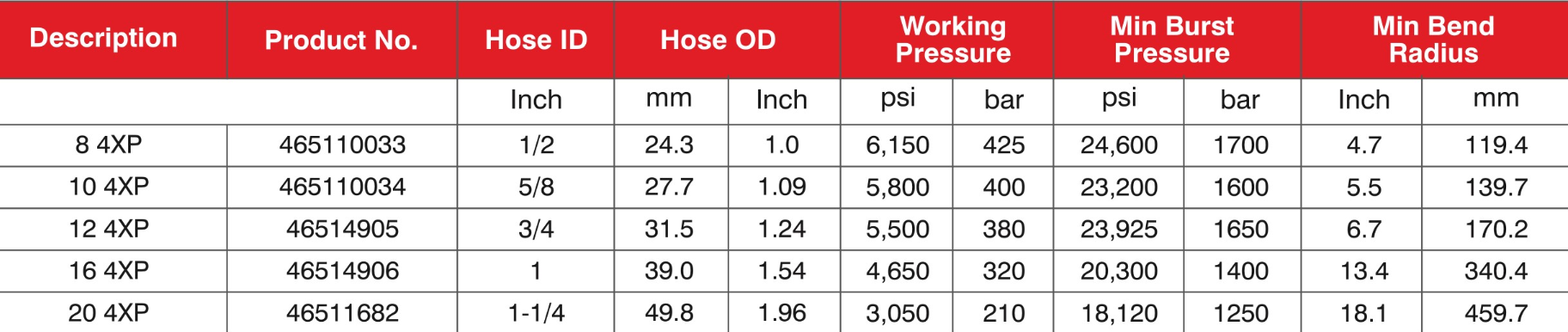

4XP Spiral Wire Hose - EN 856 4SP ISO 3862

Meets Flame Resistance Acceptance Designation MSHA IC-4/17"

Recommended for: Extremely high impulse hydraulic applications. Most flexible EN 856 4SP hose in industry. Superior impulse performance tested to 1,000,000 impulse cycles at bend radius lower than EN 856 standard. Compatible with biodegradable hydraulic fluids like synthetic ester, polyglycol and vegetable oil as well as standard petroleum based fluids

-40°C to +100°C

Construction:Tube :Black, oil resistant synthetic rubber (Nitrile].

cover :Black, oil resistant, synthetic rubber [Nitrile]

Reinforcement : Four alternating layers of spiraled, high tensile steel wire.

Coupling: GS

High Pressure

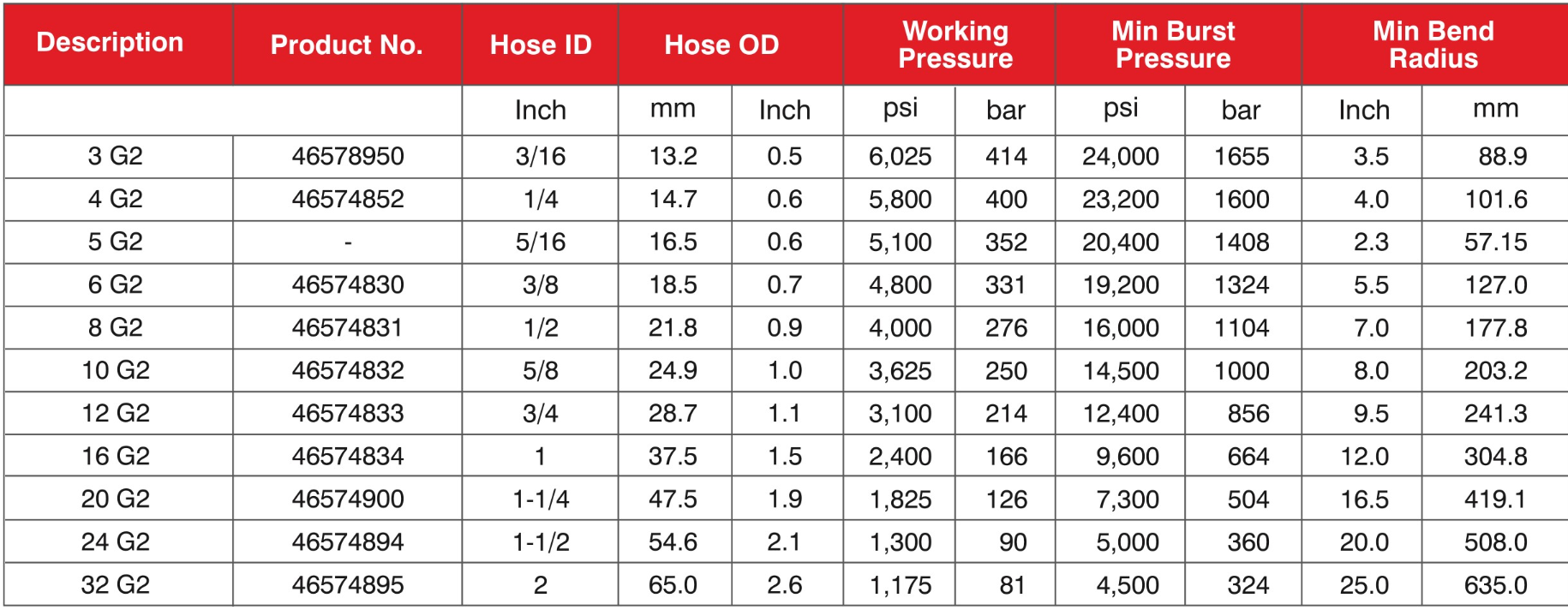

G2 2-Wire Braid Hose SAE 100R2

Meets Flame Resistance Acceptance Designation " MSHA 2G"

Recommended for: High pressure oil lines. Meets or exceeds the requirements of SAE 100R2AT. Sand performance requirements of EN 853 2SN.

-40°C to +100°C

Construction:Tube : Black, oil resistant, synthetic rubber (Nitrile - TypeC).

cover :Black, oil, and abrasion resistant thin synthetic rubber [Modified Nitrile -Type C2]

Reinforcement : 2 braid of high tensile steel wire

Coupling : G (thru -4 to -20) & GSP (thru -24 & -32)

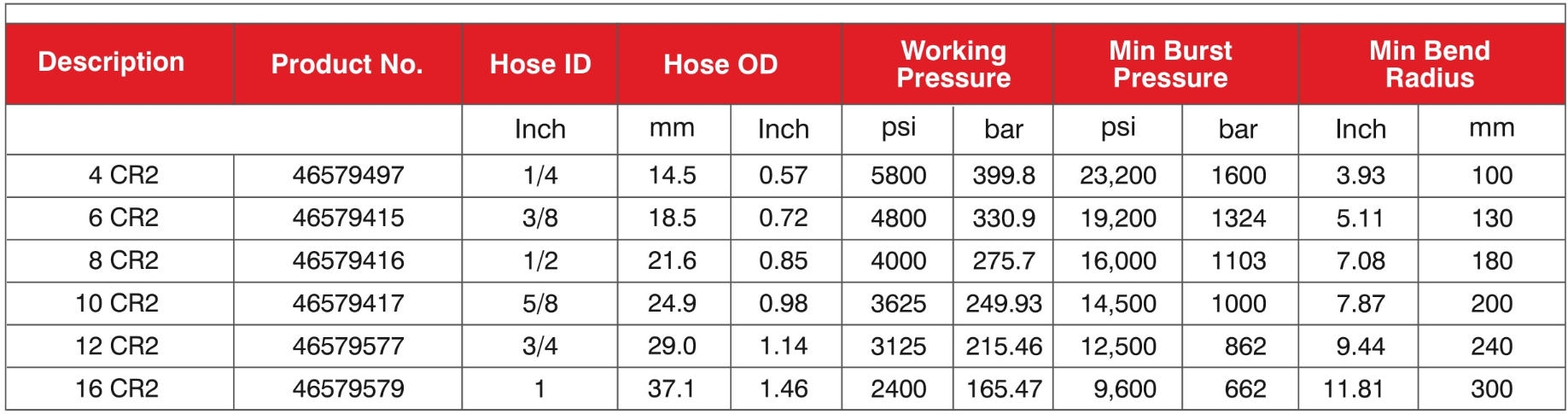

CR2-EN 853 2SN

Recommended for: Medium pressure hydraulics with low flexure/non-severe applications

-40°C to +100°C

Construction:Tube : NBR (Nitrile) based

Cover :Black, oil and abrasion resistant synthetic rubber. MSHA approved

Reinforcement : Two braids of high-tensile steel wire.

Coupling : PCK

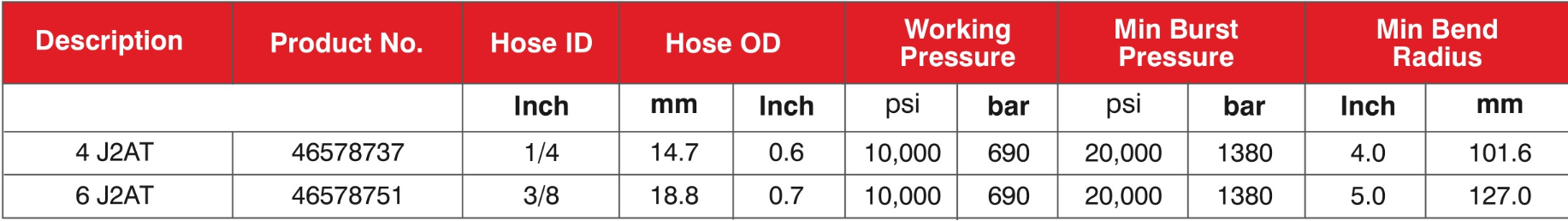

J2AT 2-Wire Braid Jack Hose

Meets Flame Resistance Acceptance Designation " MSHA 2G" Meets IJ 100 Jack Hose spec.

Recommended for: Hydraulic jack applications. Meets Material Handling Institute specification IJ 100 for hydraulic hose and assemblies used with jacking systems.

-40°C to +100°C

Construction:Tube :Black, oil resistant, synthetic rubber (Nitrile - Type C).

Cover :Black, oil and abrasion resistant synthetic rubber (Modified Nitrile - Type C2).

Reinforcement : Two braid of high tensile steel wire.

Coupling : G (MegaCrimp®)

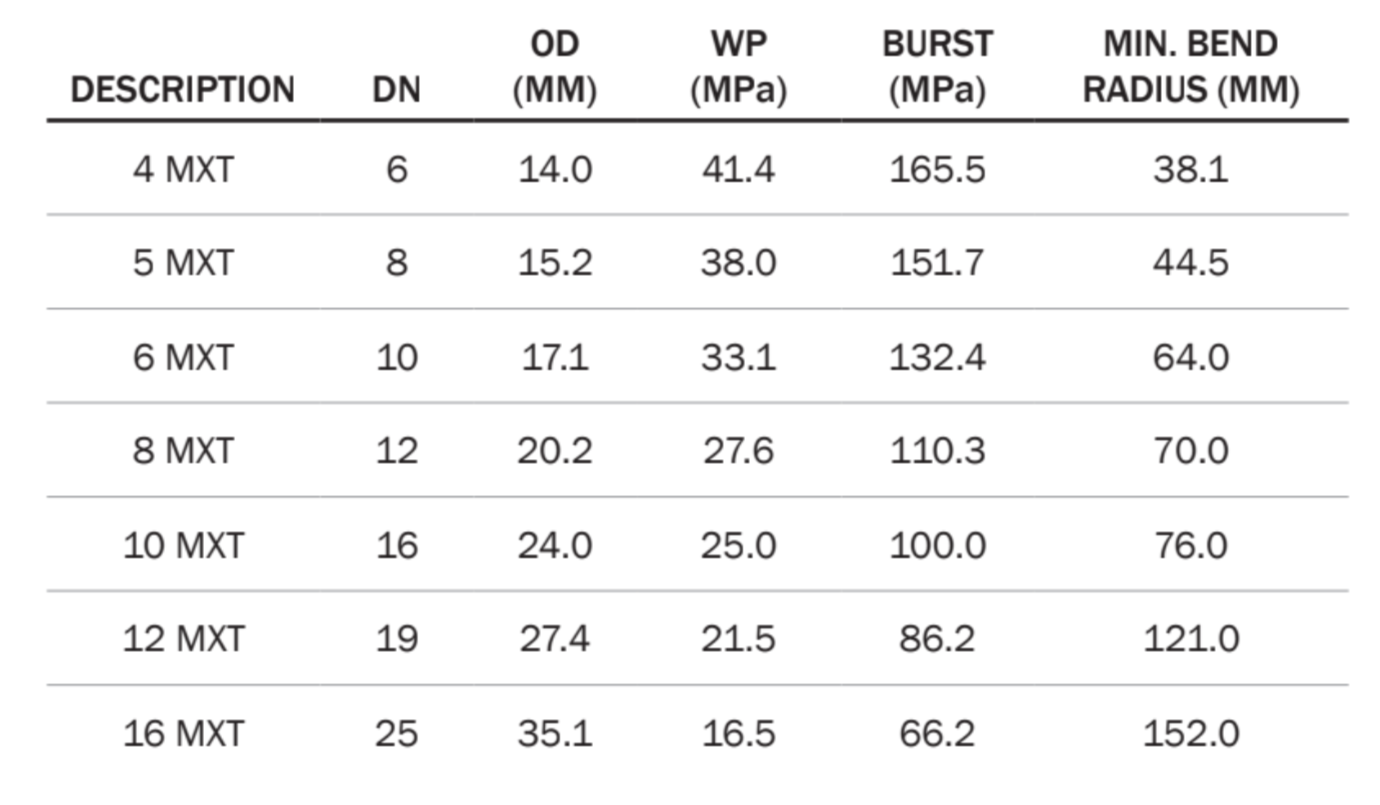

MXT

Meets SAE 100R16 & 100R17* dimension & performance; meets SAE 100R2 & SAE 100R19* performance; meets EN 853 2SN and EN 857 2SC performance (*Applies only to sizes up to and including -12 for SAE 100R17 and -8 for SAE 100R19)

-40°F to +212°F (-40°C to +100°C)

Construction:Tube :Black, oil resistant, synthetic rubber tube

Cover :Black, abrasion resistant, synthetic rubber

Reinforcement : Braided high-tensile steel wire reinforcement

Certified : MSHA Flame Resistant

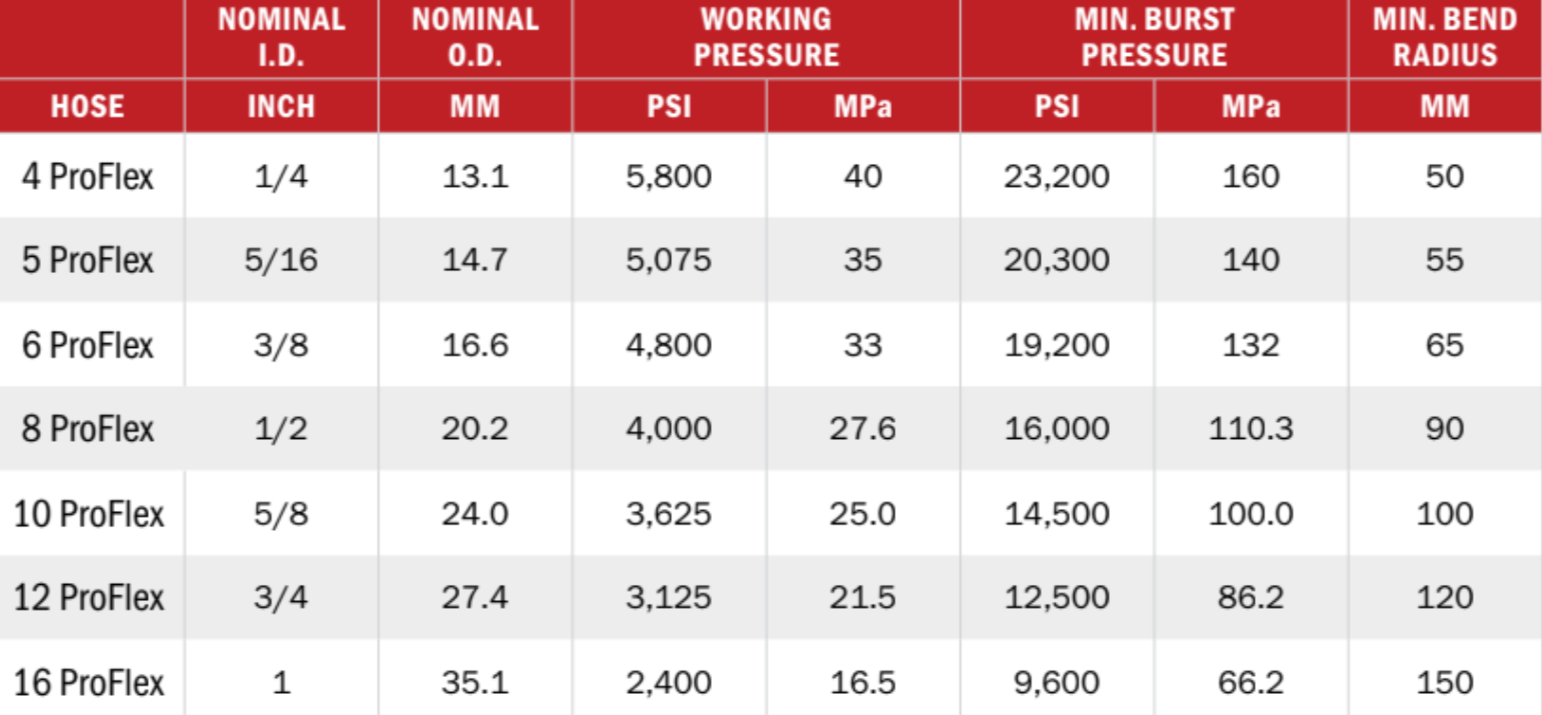

ProFLEX

ProFlex is an innovative addition to Gates PRO SERIES hydraulic portfolio. It is globally engineered with the latest advancements in material science and process technologies to deliver a compact, lighter weight and flexible solution without compromising performance.

-40°F to 212°F (-40°C to 100°C)

Construction:Tube :Black oil resistant synthetic rubber tube

Cover :Black, abrasion resistant, synthetic rubber

Reinforcement :Integrated two wire braided high tensile steel

Certified :MSHA flame resistant

Medium Pressure

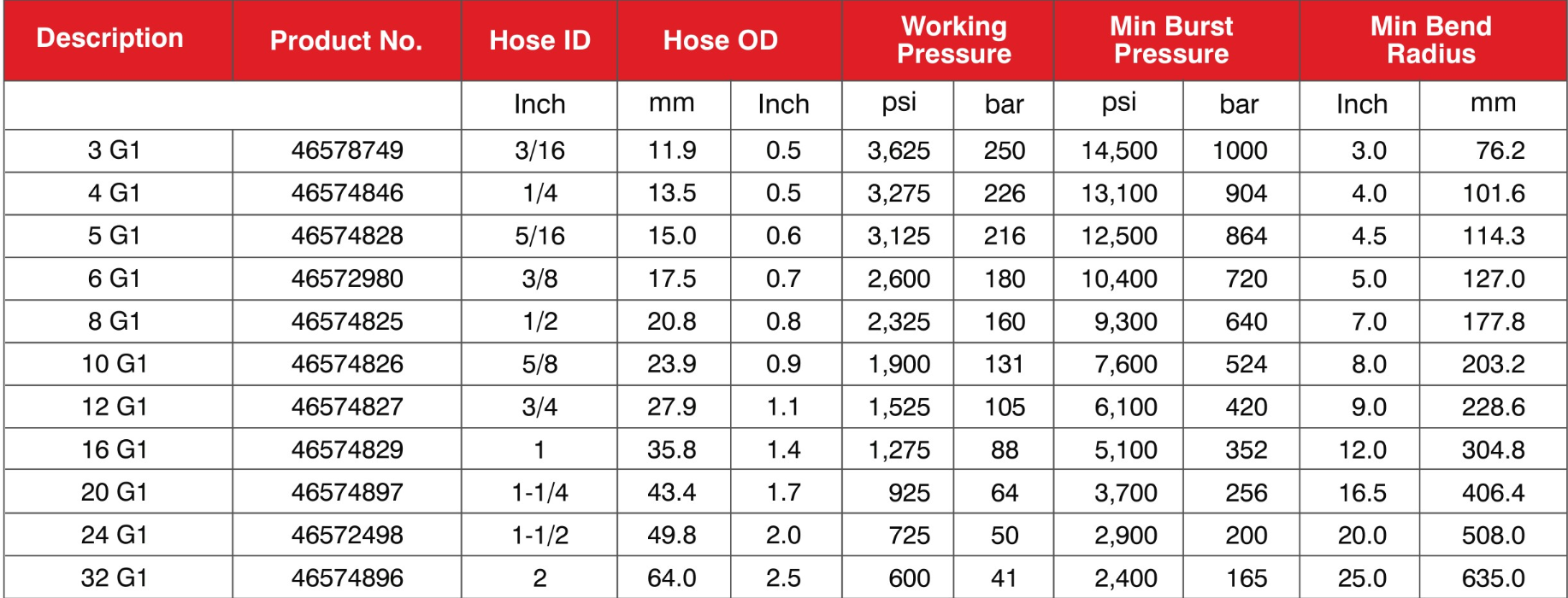

G1 1-Wire Braid Hose - SAE 100R1 Type

Recommended for: Medium pressure hydraulic lines. Meets or exceeds the requirements of SAE 100R1 Type AT and performance requirements of DIN20022 1SN/EN 853 1N. Provides tighter than standard minimum bend radius and greater flexibility for easier plumbing

-40°C to +100°C

Construction:Tube : Black, oil resistant, synthetic rubber (Nitrile-Type C).

cover : Black, oil, and abrasion resistant synthetic rubber (Modified Nitrile-Type C2)

Reinforcement : One braid of high-tensile steel wire.

Coupling : G (thru-4 to -20) & GSP (thru-24 &-32)

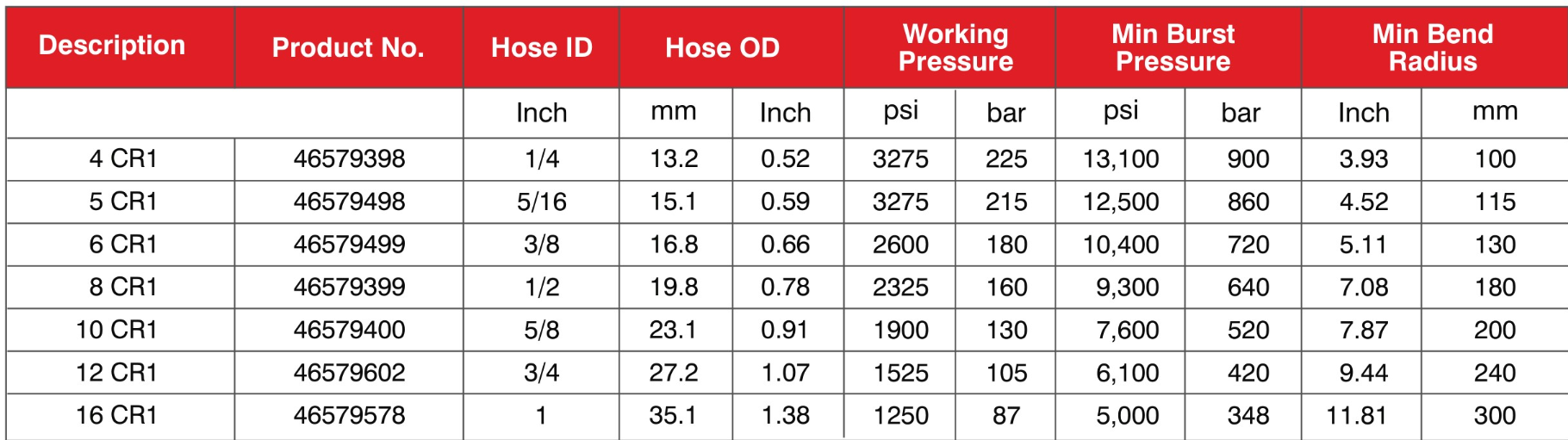

CR1 EN 853 1SN

Recommended for: Medium pressure hydraulics with low flexure/non-severe applications.

-40°C to +100°C

Construction:Tube :NBR (Nitrile) based.

Cover : Black, oil and abrasion resistant synthetic rubber. MSHA approved.

Reinforcement : One braid of high-tensile steel wire.

Coupling : PCK

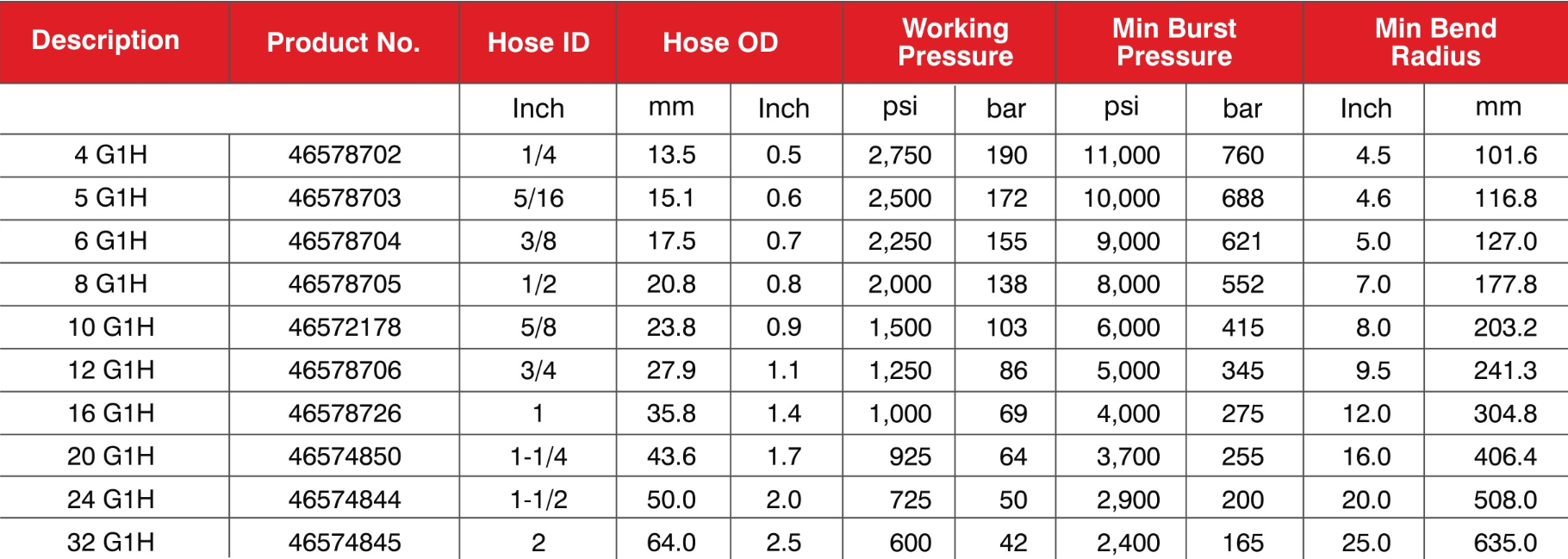

G1H High Temp 1 Wire Braid Hose-SAE 100R1 Type AT

Meets Flame Resistance Acceptance Designation MSHA 2G"

Recommended for: Medium pressure hydraulic oil lines. Meets or exceeds the requirements of SAE 100R1 Type AT

-40°C to +135°C

Construction:Tube : Black, oil resistant, synthetic rubber (Nitrile - Type C).

Cover : Black, oil, and abrasion resistant synthetic rubber (Hypalont-Type M)

Reinforcement : One braid of high-tensile steel wire.

Coupling :G (thru -4 to 20) & GSP (thru 24 & -32

Low Pressure

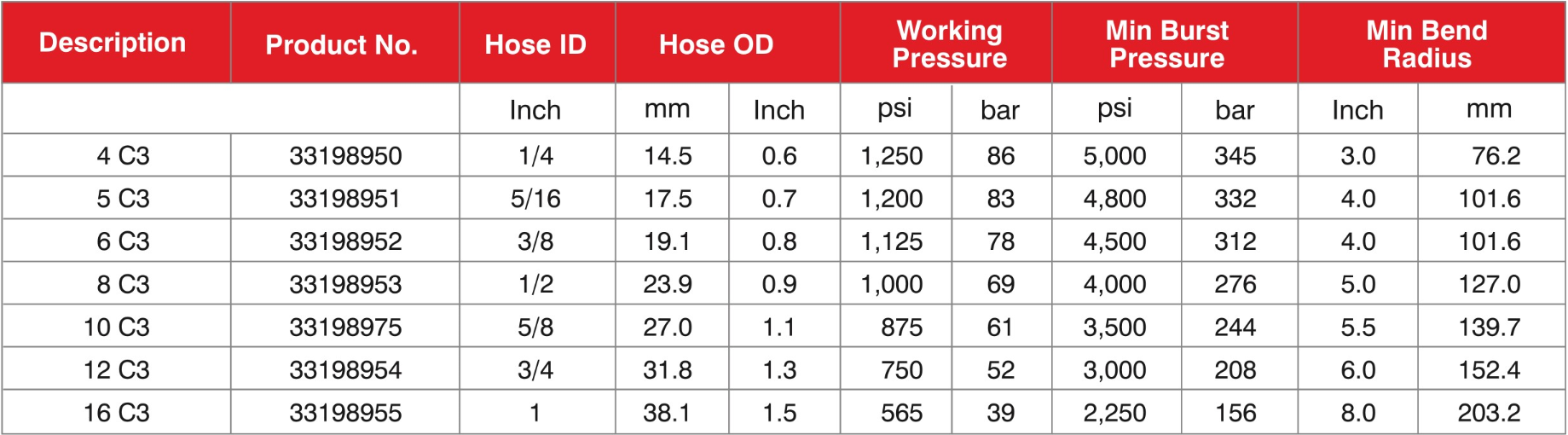

C3 Two Fiber Braid Hose-SAE 100R3

Meets performance requirements of EN 854

Recommended for: Hydraulic oil lines, anti-freeze solution or water. Meets or exceeds requirements of SAE 100R3 / EN 854.

-40°C to +100°C

Construction:Tube : Black, synthetic rubber (Nitrile).

cover :Modified Nitrile

Reinforcement : Two braid of high tenacity synthetic textile yarn.

Coupling : G (MegaCrimp)

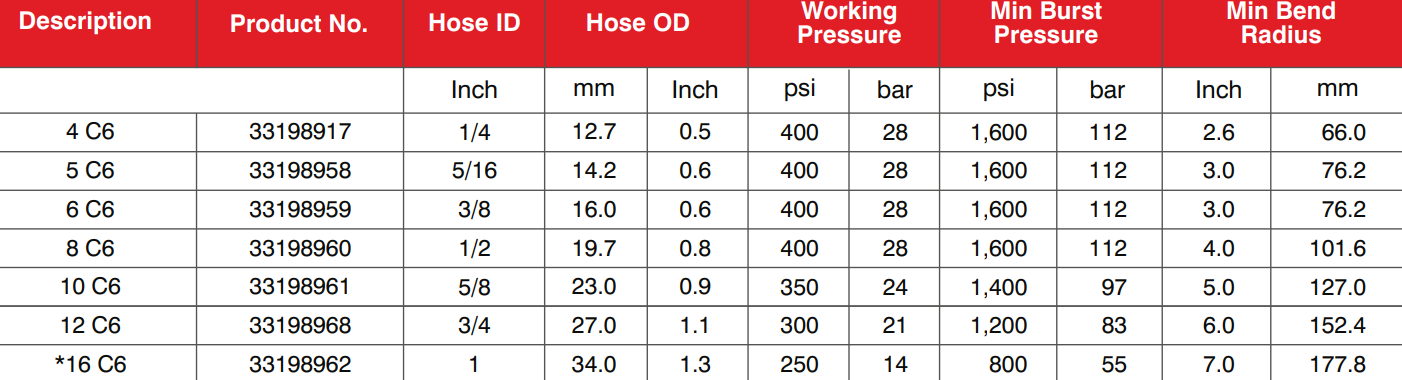

C6 One Fiber Hose-SAE 100R6

Meets performance requirements of EN 854

Recommended for: Hydraulic oil lines, heavy duty transmission anti freeze solution. Meets or exceeds requirements of SAE 100R6/EN 854.

-40°C to +100°C

Construction:Tube : Specially compounded, oil-resistant, synthetic rubber (Nitrile) Black.

cover :Oil & abrasion resistant synthetic rubber (Modified Nitrile)

Reinforcement : One braid of high tenacity yarn.

Coupling : G (MegaCrimp®)

Pilot Line Hose

Meets performance requirements of EN 854

Recommended for: Designed for hydraulic pilot control applications in confined spaces in industrial, construction and agricultural equipment. This top quality hose features superior flexibility providing a very tight bend radius as well as resistance to expansion, kinking and abrasion. P1T pilot control hose has been fully tested to meet all possible pilot control applications. It has been engineered as an assembly to ensure maximum trouble free life and avoid replacement in difficult and often inaccessible areas.

-40°C to +100°C

Construction:Tube : Oil resistant Nitrile (NBR) Reinforcement: High-tensile steel wire.

cover :Chloroprene (CR)

Reinforcement : Two braid of high tenacity synthetic textile yarn.

Coupling : P1T